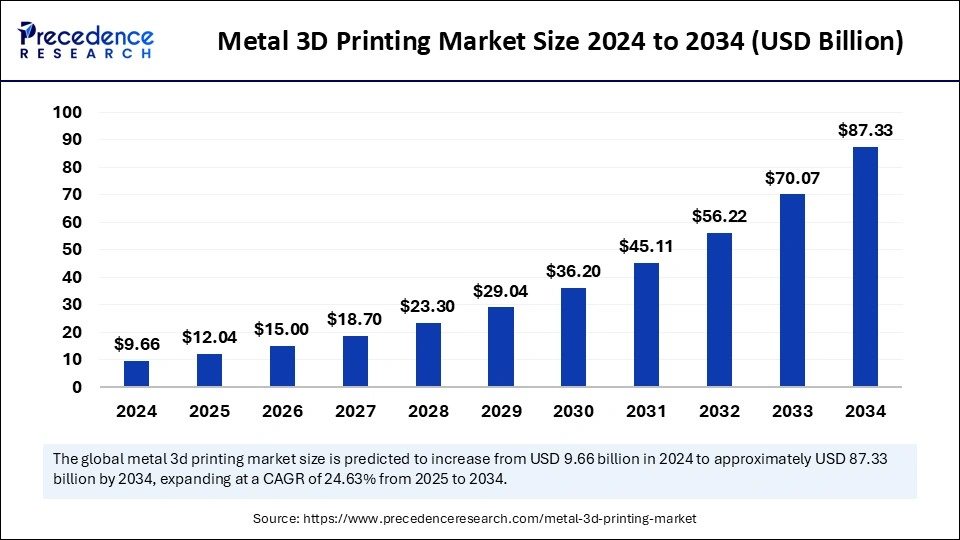

The global metal 3D printing market size was estimated at USD 9.66 billion in 2024 and is expected to surge around USD 87.33 billion by 2034, growing at a CAGR of 24.63%.

Get a Free Sample Copy of the Report@ https://www.precedenceresearch.com/sample/5840

Metal 3D Printing Market Key Takeaways

-

North America led the global market with a 34% market share in 2024.

-

Asia Pacific is expected to grow at the fastest compound annual growth rate (CAGR) during the forecast period.

-

Europe is predicted to experience notable growth throughout the forecast period.

-

The Selective Laser Melting (SLM) technology held the largest market share by technology in 2024.

-

The Electron Beam Melting (EBM) segment is anticipated to show remarkable growth with a strong CAGR between 2025 and 2034.

-

By software, the design software segment captured the largest market share in 2024.

-

The scanners software segment is expected to grow at a significant CAGR over the forecast period.

-

The hardware component accounted for 65% of the market share in 2024.

-

The services segment is expected to experience the fastest growth during the forecast period.

-

Prototyping was the leading application segment in 2024.

-

The functional parts application is predicted to experience the fastest growth over the forecast period.

-

The industrial printer segment dominated with the largest market share in 2024.

-

The desktop printer segment is expected to show a solid CAGR during the forecast period.

How Is AI Transforming Metal 3D Printing in Optimization, Quality Control, and Innovation?

AI is transforming metal 3D printing by optimizing printing parameters, ensuring higher accuracy, and reducing defects. Machine learning algorithms analyze past print data to recommend the best settings for materials and geometries, improving the quality and consistency of printed parts. AI-driven quality control systems can also detect defects in real-time, such as cracks or warping, allowing for adjustments before issues arise. Additionally, AI enables predictive maintenance by monitoring printer performance and predicting when parts may need servicing, minimizing downtime and preventing unexpected failures.

AI also plays a significant role in material development and design optimization. Through AI-driven simulations, new metal alloys and compositions are being developed, improving strength, cost-effectiveness, and lightweight properties for 3D printing. AI tools like topology optimization automate the design process, enabling the creation of stronger, more efficient structures. Furthermore, AI helps streamline supply chain management and production scheduling, ensuring that metal powders are efficiently managed and that production runs smoothly, especially in industries requiring customized parts like aerospace and healthcare.

Metal 3D Printing Market Growth Factors

-

Advancements in Technology

Technological improvements in 3D printing processes, such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM), are driving the market. These innovations enable higher precision, faster production speeds, and better material compatibility, making metal 3D printing more viable for industrial applications. -

Demand for Customization and Complex Geometries

The ability to create highly customized and complex parts without the need for expensive molds or tooling is a major growth driver. Industries such as aerospace, automotive, and healthcare are leveraging metal 3D printing to produce lightweight, intricate components tailored to specific needs, driving increased adoption. -

Cost Reduction and Waste Minimization

Metal 3D printing offers a more cost-effective production method, especially for low-volume manufacturing runs. It also reduces material waste by using only the necessary amount of metal, which is more sustainable and cost-efficient compared to traditional subtractive manufacturing processes like machining. -

Growth in Aerospace and Automotive Sectors

The aerospace and automotive industries are among the biggest adopters of metal 3D printing due to its ability to produce lightweight, durable, and performance-optimized parts. These industries use 3D printing to manufacture components that improve fuel efficiency, reduce weight, and enhance overall performance. -

Rising Demand for Rapid Prototyping

Metal 3D printing allows for rapid prototyping, enabling faster iterations and shorter time-to-market for product development. This has made it highly attractive to manufacturers in industries where speed and innovation are critical, such as medical devices, electronics, and consumer goods. -

Increased Focus on Research and Development

Companies are investing heavily in research and development (R&D) to explore new materials and applications for metal 3D printing. As material options expand, such as the development of stronger and more versatile metal alloys, the range of applications for 3D printed metal parts continues to grow. -

Government Support and Funding

Governments around the world are recognizing the potential of 3D printing for advancing manufacturing capabilities and are offering funding and incentives to promote its adoption. This support is helping drive innovation and encouraging companies to integrate 3D printing into their production processes. -

Sustainability and Environmental Concerns

Metal 3D printing is seen as a more sustainable alternative to traditional manufacturing due to its precision, which reduces waste and energy consumption. As environmental concerns grow, companies are increasingly adopting 3D printing technologies as part of their commitment to sustainability.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 87.33 Billion |

| Market Size in 2025 | USD 12.04 Billion |

| Market Size in 2024 | USD 9.66 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 24.63% |

| Dominated Region | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Technology, Software, Component, Application, Printer Type, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

The growing demand for customization, lightweight components, and complex geometries is one of the primary drivers behind the market’s expansion. Metal 3D printing is particularly beneficial for industries like aerospace and automotive, where optimized designs and reduced weight are critical. Additionally, advancements in technology, including improved materials and faster production speeds, are further accelerating adoption. The market is also driven by the need to reduce material waste, improve manufacturing efficiency, and cut costs, especially for low-volume production runs.

Opportunities

There are significant opportunities for growth, particularly in the expansion of material options and the use of metal 3D printing in the production of functional parts rather than just prototypes. As R&D investments continue, new metal alloys and more specialized materials are emerging, broadening the applications of 3D printing. Furthermore, the increasing shift toward digital manufacturing and on-demand production is opening new avenues for customization, especially in industries such as medical devices and consumer goods.

Challenges

Despite the promising growth, the Metal 3D Printing Market faces challenges such as high initial investment costs and the need for skilled labor to operate sophisticated machinery. The relatively slow production speed compared to traditional methods can also limit its scalability for mass production. Moreover, standardization and quality control remain concerns, as the industry lacks a universal framework for ensuring consistent results across different machines and materials. Additionally, the cost of metal powders, which can be high, poses a barrier to widespread adoption.

Regional Insights

North America, particularly the U.S., is a dominant player in the Metal 3D Printing Market, driven by the aerospace, automotive, and defense industries. Europe is also seeing steady growth, with countries like Germany leading in industrial applications. The Asia-Pacific region, especially China and Japan, is experiencing the fastest growth, driven by the increasing adoption of 3D printing technologies in manufacturing and the expansion of industries such as automotive and healthcare. Latin America and the Middle East are also witnessing increased interest, although at a slower pace.

Metal 3D Printing Market Companies

- Cognex Corporation

- Basler AG.

- Sick AG

- 3D Systems Corporation (U.S.)

- Stratasys Ltd.

- Renishaw plc

- General Electric Company

- Carpenter Technology Corporation

- Materialise NV

- Voxeljet AG

- Sandvik AB

- EOS GmbH Electro Optical Systems

Recent Developments

- In October 2024, Anugrah Cipta Mould Indonesia (ACMI) developed a novel additive manufacturing center to support its production of footwear moulds, along with multiple Farsoon 3D printing systems, including the FS200M dual-laser system and FS350M quad-laser system.

- In March 2025, the Bambu Lab H2D is an all-in-one desktop fused deposition modeling system comprising 3D printing, laser engraving, cutting, and plotting functionality. It launched its next-generation 3D printer.

- In November 2024, 3D Monotech, the 3D vertical of Monotech Systems Limited, a leading provider of advanced 3D printing solutions, announced the launching of the revolutionary Markforged FX10 3D printer in India, the world’s first metal and advanced composites 3D printer, to produce high-performance parts directly from digital designs, accelerating innovation and streamlining production processes.

Segment Covered in the Report

By Technology

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Inkjet printing

- Electron Beam Melting

- Laser Metal Deposition

- Laminated Object Manufacturing

- Electron Beam Freeform Fabrication

- Selective Laser Melting

By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

By Component

- Hardware

- Software

- Services

By Application

- Prototyping

- Tooling

- Functional Parts

By Printer Type

- Desktop Metal 3D Printer

- Industrial Metal 3D Printer

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Also Read: Telecom Tower Market

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/